HEADLAMP SWITCHING MODIFICATION MARK 2

DO NOT BUILD UNTIL THIS NOTICE IS TAKEN DOWN

IT'S A DESIGN IN PROGRESS AND IS INCOMPLETE BEFORE THEN

This design improves vehicle headlamp brightness by

reducing the voltage drop associated with the length and gauge of

wiring normally fitted to the headlamp circuits.

It is designed specifically for the CitroŽn BX and for the

use of BXClub members - see

BXClub.co.uk and has

the same functionallity as the original design.

OVERVIEW

The CitroŽn BX has basic switching for sidelights, dip and main beams. When

both sidelights and ignition are on the dip filaments are driven at low

intensity - "dim-dip" - this prevents the car being driven on sidelights

alone.

The electronics in this design is only responsible for the dim-dip function

and only differs from the original in that the brightness of dim-dip is

adjustable and almost entirely avoids the slight inefficiency

of the original resistive design.

Dip beam and main beam functions are operated by relays with power being

derived from a new high current (and therefore low voltage drop) wire direct

from the battery.

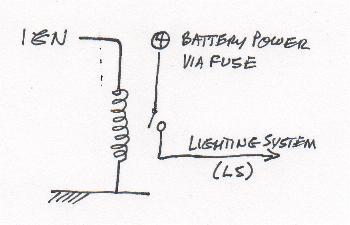

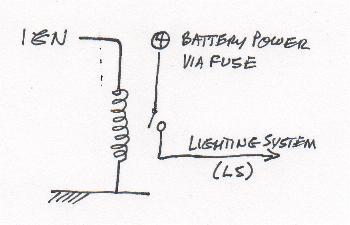

POWER SOURCE

In order to reduce voltage drop to the headlamps a high current wire should

be fed from the battery to the headlamp area to feed the new control

arrangement - this should be fused at the battery end to reduce the risk

of fire in the event of serious front end damage to the vehicle which could

short out the wire to chassis. A 20 amp fuse should suffice unless high

power filament are used and additional lighting such as spotlamps are

driven from the same wire.

One way to provide power to the electronics is by using a relay.

MAIN CIRCUIT

CIRCUIT DESCRIPTION

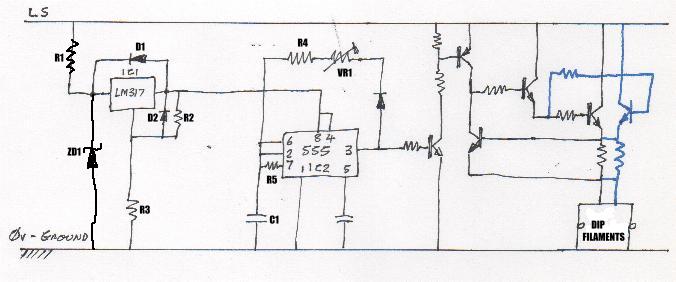

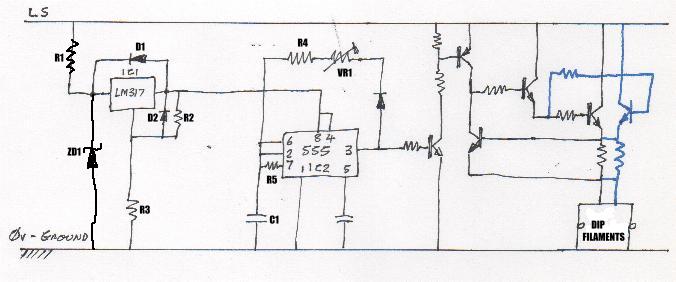

IC1 provides stable regulated power for IC2. A further description of

the LM317T including this particular circuit configuration is at

IC2 is an oscillator with an adjustable mark / space ratio which drives

pulses into the next stage. A more detailed description of the 555 timer

including this particular circuit configuration is at

The remaining circuit consists of a power buffer with current limiting

and is adequately described on the LM317T page link as above.

The circuit drives power in the form of pulses to the dip filaments.

The frequency of these pulses is too high for the filaments to respond so

they glow in response to the average amount of power delivered to them.

When the circuit is started the filaments are very low resistance and the

current limiter will operate to protect the drive transistors but when

the filaments have warmed to their operating temperature their resistance

will be high enough for the limiter not to operate. At this point the output

transistors will either be "on" or "off" and so will waste very little power

and should run dissipate very little heat.